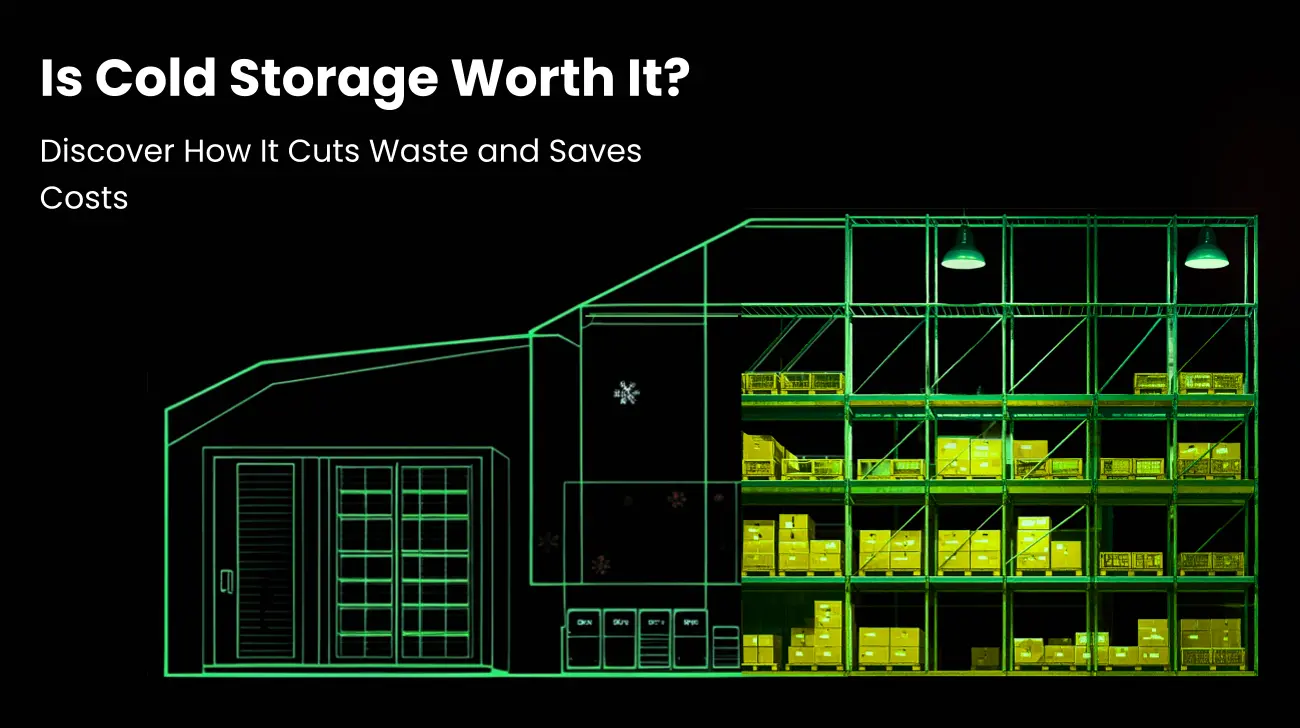

Cold Storage Success Story: Efficient Cooling Design for Freshness and Logistics

Introduction: Why Cooling Design Matters More Than Ever

In today’s fast-moving supply chains, freshness is not just a quality factor — it is a business advantage. From food cold storage facilities to pharmaceutical logistics, companies depend on temperature controlled storage to maintain product quality and reduce loss. Yet many businesses struggle with inconsistent temperatures, high energy bills, and delayed logistics.

This cold storage success story explores how an organization transformed its refrigerated warehouse using efficient cooling design, resulting in improved freshness, stronger chain of logistics, and measurable operational gains. The lessons from this real-world case study provide practical insights for anyone involved in cold chain management, refrigerated logistics solutions, or industrial cooling design.

The Challenge: Growing Demand, Rising Spoilage

A regional distributor handling frozen food and dairy products faced increasing challenges as demand grew. Their existing facility was designed for smaller volumes, and the cooling system lacked modern optimization.

Key problems included:

- Uneven temperature distribution in storage zones

- Product spoilage during peak demand periods

- High energy consumption from aging refrigeration units

- Delays in dispatch due to inefficient layout

- Difficulty maintaining consistent movement of logistics

These issues directly affected customer satisfaction and operational profitability. It became clear that a full cold room design optimization was required rather than small fixes.

Project Goal: Smart Cold Storage Design for Supply Chain Performance

The objective was simple but ambitious:

Create an energy efficient design that improves freshness while supporting faster logistics movement.

The team approached the project as a CSD case study, focusing on long-term performance instead of short-term repairs. Their strategy centered on three pillars:

- Precision cooling technology

- Layout redesign for logistics efficiency

- Intelligent monitoring for temperature control

This approach aligned with modern cold chain optimization strategies used in advanced refrigerated warehouse solutions.

The Solution: Efficient Cooling Design in Action

1. Precision Cooling Zones

Instead of maintaining one temperature across the entire warehouse, the facility introduced multiple cooling zones based on product type:

- Frozen food storage solutions at deep-freeze levels

- Dairy cold storage logistics zones with stable mid-range cooling

- Fast-moving products near dispatch zones for quick access

This zoning approach reduced compressor overload and minimized temperature fluctuations.

2. Airflow and Insulation Improvements

One major discovery was inefficient air circulation. By redesigning airflow channels and upgrading insulation, the facility achieved:

- Faster temperature recovery after door openings

- Reduced thermal leakage

- Consistent cooling across shelves

This step alone significantly improved the impact of cooling design on product freshness.

3. Smart Monitoring System

Sensors were installed throughout the warehouse to monitor:

- Temperature variations

- Humidity levels

- Energy consumption

- Equipment performance

Real-time alerts allowed managers to act immediately, preventing spoilage and downtime. This transformed the facility into a data-driven cold storage project case study.

Logistics Transformation: Cooling Meets Movement

Cooling efficiency alone does not guarantee success. The team redesigned internal product flow to support cold storage logistics and faster dispatch.

Improvements included:

- Dedicated loading zones connected to refrigerated trucks

- Shorter internal movement routes

- Faster pallet access through optimized rack design

- Scheduled loading windows to reduce door-open time

As a result, logistics delays dropped significantly, making this project a strong logistics efficiency case study.

Results: Measurable Business Impact

Within six months of implementation, the results were clear:

- Product spoilage reduced by nearly 30%

- Energy consumption decreased by about 20%

- Dispatch speed improved due to better layout

- Temperature stability increased across all zones

- Customer complaints related to freshness dropped dramatically

This demonstrates how reducing spoilage through cold storage optimization directly influences profitability and operational trust.

Industry Insights: Why This Case Study Matters

This success story reflects a larger trend in cold chain industries. Whether managing a food cold storage facility or planning a pharma cold storage design, businesses are shifting toward smarter, more efficient systems.

Key lessons include:

- Cooling design should match product categories

- Logistics planning must be integrated with refrigeration

- Data-driven monitoring improves decision-making

- Efficiency reduces both waste and energy cost

Modern refrigerated logistics solutions now focus equally on engineering design and workflow management.

How This Supports Future Cold Chain Growth

As supply chains become more global and customer expectations rise, and this facilities must evolve beyond traditional models.

Future-ready facilities will focus on:

- AI-assisted temperature optimization

- Predictive maintenance for cooling systems

- Sustainable energy usage

- Smart automation integration

The success of this project proves that efficient cooling design is not just a technical upgrade — it is a strategic investment supporting long-term cold chain logistics performance.

Key Takeaways

What made this cold storage success story successful?

- Zoned cooling improved temperature controlled storage

- Optimized airflow enhanced freshness

- Smart monitoring reduced risks

- Logistics-focused layout boosted efficiency

- Energy optimization lowered operating costs

Main outcome: Better freshness, faster logistics, and stronger operational performance.

Final Thoughts

This cooling design success story highlights how thoughtful planning and engineering can transform an ordinary facility into a high-performing refrigerated warehouse. The combination of smart cooling, logistics alignment, and data-driven management created a scalable system capable of handling growing supply chain demands.

For businesses operating in food, dairy, pharmaceutical, or frozen product sectors, this cold storage case study offers a clear message:

Efficient cooling design is no longer optional — it is the foundation of reliable freshness and successful logistics.

By investing in intelligent cold storage strategies today, companies can build stronger supply chains, reduce waste, and deliver consistent quality tomorrow.